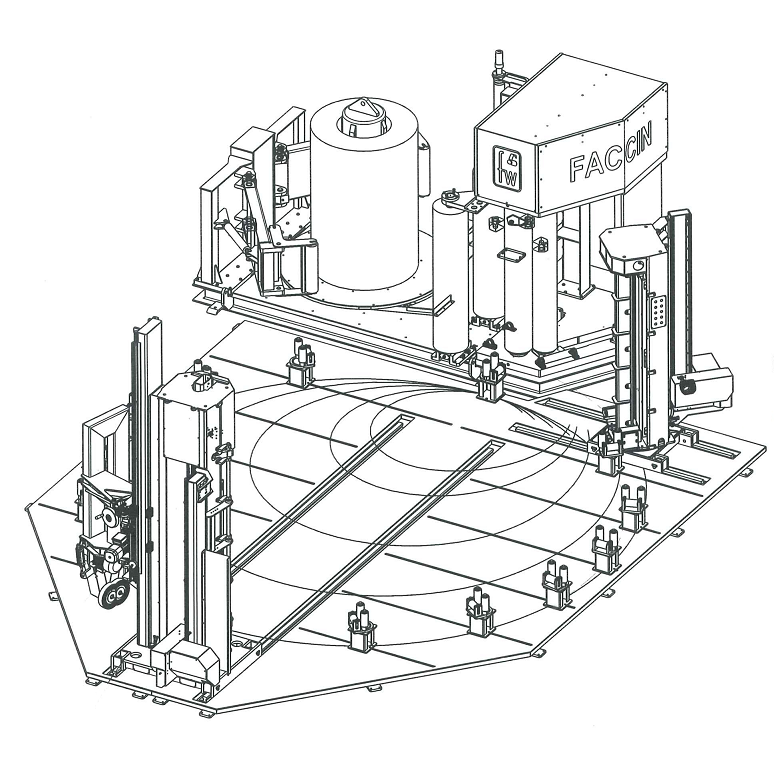

Automatic line consists of the following Units:

自動線(xiàn)由如(rú)下裝置或單元組成:

1) Vertical Bending unit 立體開卷單(dān)元

2) Longitudinal seamer for cutting unit 縱縫切割單元

3) Longitudinal seamer for welding unit 縱縫焊接單元

4) Internal External welded joint cleaner

內部和外部焊縫處理裝置

5) Platform to support move the ferrule

支撐和移動圓筒的工作平(píng)台

1- Vertical Bending Unit

立式開卷單元

The unit consists of the following configurations該單元包(bāo)含(hán)如下配置:

(1)Decoiling system features 開卷係統裝置

- Decoiler to handle 14 tons coils開卷機處理14噸卷;

- The decoiler can work independently synchronized with the plate rolling machine 開卷機可(kě)獨立工作或與卷板機同步工作;

- The decoiler is controlled by the Siemens NC 開卷機由西門(mén)數控控製;

- The coil rotation is obtained by a hydraulic motor gearbox卷材的旋轉由液壓馬達和齒輪箱提供;

- The decoiler is equipped with a self-aligning clamping system to avoid the coil opening開卷機設有自動夾緊係統,防(fáng)止卷材向外打開;

- Safety system around the decoiler are included in the supply開卷機周(zhōu)圍的安全係統包括在供(gòng)應範圍內;

(2) Vertical Bending Machine立式卷圓機

- Vertical 3 rolls machine with asymmetric design不對稱設計的(de)立式三輥機

- 3 rolls independently motorized3個(gè)輥獨立驅動

- Hydraulic rolls movement工作輥液壓移動控(kòng)製

- Electronic balancing system of the rolls工作輥電子平衡係(xì)統控製

- Variable rotation speed可變卷板速度

- Rolls coated to with urethane to prevent stainless steel contamination 工作輥包裹聚氨(ān)酯以防止對不鏽鋼汙(wū)染

-Automatic rolls positioning 工(gōng)作輥自動定位功能

- Protected guide rolls for alignment correct feeding of the plate保護導向輥,用於板的對齊和(hé)正確進給機

- Control console on wheels輪式移動控製台

- Siemens NC control西門子數控(kòng)

- Safety device with immediate stop of every movement安全裝置,可立(lì)即停止任(rèn)何(hé)動作(zuò)

- User maintenance instructions book使用維護說明書

- The machine is designed manufactured according to Machinery Directive 2006/42/EC該機器是根據機械規則2006/42/EC設計和製造(zào)的

(d)Other Accessories 其他配置

- Coil tilting system卷材傾斜係統

The coil tilting system turn the coil horizontal to vertical position卷材傾斜(xié)係統可將卷材從(cóng)水平位置(zhì)轉到垂(chuí)直位(wèi)置;

- Paper recovery roll 紙張回收輥

The paper recovery roll wraps the paper that is inside the coil紙張回收輥將卷材內的包裝紙(zhǐ)張纏繞起來(lái);

- Plastic film applier rolls塑料膜塗輥(gǔn)

2 plastic film applier rolls apply the protective film inner outer to the plate兩個塗(tú)膜輥用戶保護板材內外保護膜;;

- Wireless remote control無線遙控裝置

Wireless remote controls the machine movements for an easier operation無線遙控器控製機器運行,操作更方便;

1- Longitudinal seamer for cutting unit縱縫切割單元

a) along the rails of the platform to compensate different ferrule’s diameters沿平台軌道補償不同套(tào)圈(quān)直徑

b) around its vertical axis to have, always, a cut with 90° when the ferrule’s diameters vary當工件直徑變化時,圍繞其垂直軸進行90°切割。

- Back up cutting support complete with hood to recovery the cutting fumes (fun system filter at customer’s supply) 預留切割支架和機罩,回收切割煙霧(風扇和過濾器由客戶自行提供)。

- Carriage-holder beam with grinded hardened guides ball recirculation block guides 帶有(yǒu)研(yán)磨和硬化導軌和鋼球再循環塊導軌(guǐ)的(de)托架固定梁。

- Welding head-holder truck (X axis) powered by a gear-motor brushless in a.c. complete of resolver, with speed position adjustable by N.C. On the carriage is installed a pneumatic vertical slide to support the cutting head焊接頭固定架小車(X軸)由齒(chǐ)輪電機驅動(dòng),無刷交流,配有旋轉變壓器,速度和位置可由數控調(diào)節。托架上安裝了一個氣動垂直滑動裝置,以支撐切割頭。

- Automatic cycle managed by the PLC of N.C. 數控PLC控製(zhì)的自動循環

- Device for the delay of the displacement of the carriage managed by N.C. 數控管理的小車位移延遲(chí)裝置。

- Numerical control with 1 axes (X Axis), equipped with HMI colour touch screen (English/Chinese language interface) to control the torch position the cutting speed. The system, complete with PLC, is equipped with USB port software package to connect an external personal computer ( included in the supply), to use both for the off-line programming, the back-up of the recorded programs the after-sale service by internet connection.1個數控軸(X軸),配置HMI彩色觸摸屏(英文/中文界麵),控製焊槍位置和切割(gē)速度。該(gāi)係統配有可編程(chéng)邏輯控製器(PLC),配有USB接口和軟件包,用於連接外部個人計算機(不包括(kuò)在供貨範圍內),用於(yú)離(lí)線編程、備份錄製的程序和通(tōng)過互聯網連接的售後服務。

- Electrical panel installed on the machine complete with console for the operator.安裝在(zài)機器上的(de)電氣麵板,配有操作員控製台。

1- Longitudinal seamer for welding unit

縱縫焊接單元

Copper bar in alloy Cr-Zr with double cooling circuit鉻鋯合金銅導杆,雙冷卻(què)回路。

- Chiller for cooling of the bar with close circuit fast connection 具有閉合電路和快速(sù)連接的用(yòng)於冷卻導杆的冷卻器,

- Support of the copper bar with ferrous material. This support has a motorized lifting for easy unloading of the welded ferrule. With this solution the customer has to lift the ferrule of few centimetres to remove it the seamer, instead of lifting for its total height if the copper bar

has scissor opening as our competitor solution有色金屬材料支架支撐(chēng)銅導杆。該支架配有電動升(shēng)降裝置,便於(yú)焊接套圈(quān)的卸載。使用這種(zhǒng)方式,客戶必須提起圓筒幾厘米,才(cái)能(néng)將其從焊接頭上拆下,不需要提升到高點。

- Carriage-holder beam with grinded hardened guides ball recirculation block guides.帶有研(yán)磨和硬化導軌和鋼球再循(xún)環塊(kuài)導軌的托架固定梁

- Welding head-holder truck (X axis) powered by a gear-motor brushless in a.c. complete of resolver, with speed position adjustable by N.C. On the carriage is installed a pneumatic vertical slide to support the welding torch頭固定小車(X軸)由齒輪交流無刷電機驅動,配有旋轉變壓器,速度和(hé)位置可由數控調節。在托架上安裝了一個氣(qì)動垂直(zhí)滑動裝置(zhì),以支撐焊槍

- Center device of the copper bar support with automatic connection for infeed gas water copper bar cooling銅杆支架中心裝置,帶自動連接,用於(yú)進料氣體(tǐ)和銅杆冷卻水。

- Automatic cycle managed by the PLC of N.C. 數控PLC控製的自動循環。

- Pneumatic linear centring device.氣動線性對中裝置(zhì)

- Current sensor. 電流(liú)傳感器。

- End welding fading control managed by N.C.由數控管理的端部(bù)焊接頭漸退控製(zhì)。

- Device for the delay of the displacement of the carriage managed by N.C.數(shù)控(kòng)管理(lǐ)的小車位移延遲裝置。

- Inferior back up gas injection into the bar complete of electrovalve flux meter to help full penetration protect the inner welded pool oxidation during the welding/cooling phase. (It is a must when you weld stainless steel, titanium, aluminium to have the inner side of the welded pool with the same technical features (corrosion resistance) of the basic material; without this accessory you can easily have problem of pitting corrosion along the joint after few months在焊接/冷卻階段,將劣質備用氣(qì)體注入電動閥和流量計的杆中,以幫助完全滲透並保護內部焊接池(chí)免受氧化。(焊接(jiē)不鏽鋼、鈦、鋁時,必須使焊接池(chí)的內(nèi)側具有與基(jī)本材料相同的技術特性(耐腐蝕性);如果(guǒ)沒有此附件,幾個月後,很容易(yì)出現沿接頭的點蝕問題(tí)。

- Superior back up gas injection “trailer” water cooled complete of electro valve flux meter to protect the upper weld pool oxidation during the welding/cooling phase. (It is a must when you weld stainless steel, titanium, aluminium to have the upper side of the welded pool clean with the same technical features as the basic material black; so you do need to use chemical product to clean it you do have problems of pitting corrosion)優質備(bèi)用氣體注入“拖車”水(shuǐ)冷式,配有電子閥和流(liú)量表,以保護焊接/冷卻階段的上(shàng)部熔池免受氧化。(焊接不鏽鋼、鈦、鋁時,必須使焊接池的上側清潔(jié),並具有與基(jī)本材(cái)料相(xiàng)同的技(jì)術特性,且不發黑;因此,不需要使用化學(xué)產品(pǐn)清潔(jié),也不(bú)存在點蝕問題)

- Numerical control with 1 axes (X Axis), equipped with HMI colour touch screen (English/Chinese language interface) to control the torch position, the welding speed. The system, complete with PLC, is equipped with USB port software package to connect an external personal computer ( included in the supply), to use both for the off-line programming, the back-up of the recorded programs the after-sale service by internet connection.1個數(shù)控軸(X軸),配有HMI彩(cǎi)色觸摸屏(英文/中文界麵)控製焊槍位置和焊接速(sù)度。該係(xì)統配有可編程邏輯控製器(PLC),配有USB接口和軟件包,用於連接外部個人計(jì)算(suàn)機(不包括在(zài)供貨(huò)範圍內),用於離線編程(chéng)、備份(fèn)錄製(zhì)的程序和通過互聯網連接的售後服務(wù)。

- Electrical panel installed on the machine complete with console for the operator機器上的電氣控製麵板是安裝在操作員控製台。

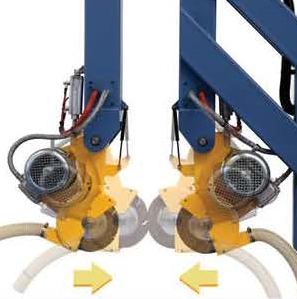

1- Internal External welded joint cleaner內部和外部(bù)焊縫處理裝置

Inner/outer vertical cleaning plant with a couple of motorized brushes at fixed rotation speed installed on a U device (useful length of 1600 mm) that is vertically moveable on a beam at adjustable speed by potentiometer. Each brush unit has a pneumatic cylinder device as release to compensate the wearing of it, at the same time by air pressure regulator is possible to adjust the cleaning force. 內/外垂直清洗設(shè)備,帶(dài)有兩個(gè)固定轉速的電動刷子,安裝在U形裝置(有效長度為1600 mm)上,該裝置可通過電位計在橫梁上以可調速度垂直移動。每個刷子單元都有一個氣缸裝置作(zuò)為釋放和補償它的磨損,同時通(tōng)過氣壓調節器可以調節清洗力。

The cleaning plant is mounted on the front of longitudinal welding seamer so it’s easy to compensate the different ferrules diameters more over we are always at 90° with the welede joint without needs radial compensation as necessary with other solution the inner/outer cleaner is installed on a separate area。清洗設備安裝(zhuāng)在縱向焊接機的前部,因此可以很(hěn)容易地(dì)補(bǔ)償不同的(de)金屬箍直(zhí)徑,超過90度時,我們總是與焊接接頭成90度角(jiǎo),而無需進行徑向補償,必要時還可以采用其他解決方案,其(qí)中內/外清洗機安裝在單獨的區域

1- Platform to support move the ferrule

支撐和移動圓筒的工作平台

- Welded metal structure that is the platform with walk-floor on which are installed a series of idle stainless steel rolls (moveable manually along the radius of the platform) to help the operator during ferrule’s loading phases for the following phases焊接金屬結構,即在平台上安裝一係列從動不鏽鋼輥(可沿平台半(bàn)徑手動移動)的帶走道的平台,以幫助操作(zuò)員在圓筒加載階段進行以下階段:

Ø Cutting 切割

Ø Welding 焊接

Ø Internal/External cleaning 內部/外部表(biǎo)麵處理

On the platform there are also two motorized unit (one close to the bending unit in fix position one in between cutting welding station radially moveable) at fixed speed to move the ferrule one working station to the next one平台(tái)上還(hái)有兩個固定速度的(de)電動裝置(一個靠近固定位(wèi)置的彎曲裝置,另一個位於(yú)徑向移動的切割和焊接站之間),用於將圓筒從(cóng)一個工(gōng)作站移動到下一個工作站。